[*Embedded links are to UK sites. International versions can be found at the end of this post].

We recently had our tumble dryer running a load of washing when the note of the motor suddenly pitched up an octave. Checking on it, I found the drum was no longer spinning. After unplugging the power to the machine, I tried turning the drum by hand and was still able to spin it easily. This suggested that the drive belt had broken (the drum still turned and the motor still ran - the higher pitch indicating that it was spinning faster than before without the load of the drum to turn as well).

The replacement belt from espares.

I decided to repair it myself and ordered a replacement belt from espares.co.uk

I've used espares a few times in the past and have always found the parts to be of high quality and reasonably priced.

When the new belt arrived I took the dryer off the stack and set about getting it open to work on. The top of the unit came off easily enough after removing two screws from the back. I could immediately see that the drive belt had broken as there was no sign of it other than the polished ring around the drum where it would normally be.

I then took the side panel off. This was a little trickier as it is held in place by six or seven screws down the back and two screws in the top front. The base of the side panel hooks into some retaining slots so it has to be slid backwards in order to be fully removed. This was impossibly hard. At least until I realised there were still two screws holding it on! One was under the front corner, coming up from underneath, and the other was hidden behind a plastic panel. Once those were out, the side came off with no trouble.

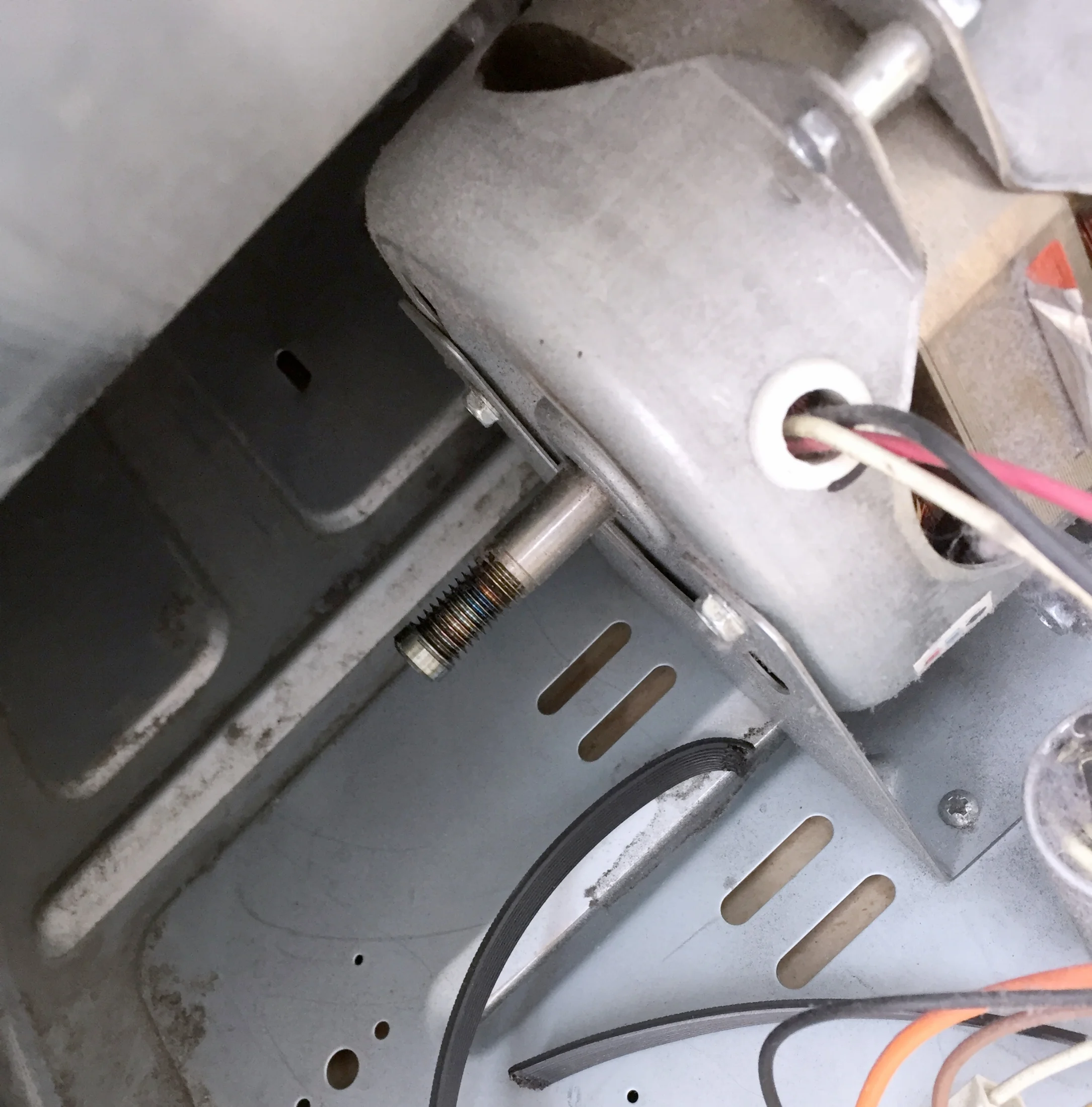

The motor and spindle with the broken belt.

With the side removed I could see under the drum. There lay the broken drive belt.

Now the hard part. In order to get the new belt around the drum you have to pull the front of the machine, make a gap between the drum and the door frame, and lower the new belt in. I had to take the top screws out of the front of other side panel to do this. Once the belt was around the drum, I replaced the two screws again.

Now the REALLY hard part. The belts are designed to be tight. The only thing that turns the drum is the friction between the moving belt and the metal of the drum. I had to somehow stretch the belt to go under the spindle on the motor. This was NOT easy.

Dryer back on the stack.

I wound up with my feet braced against the dryer pulling on the belt with all my strength. It took a good ten to twenty minutes of working the belt around and pulling before I was just able to get it under the spindle. In hindsight I should have spent some time stretching the belt before putting it around the drum.

With the belt in place, I put the side and top panels back on the machine and lifted it back onto the stack. I ran the securing strap back over the top and ratcheted it tight. I refitted the vent hose to the back of the dryer and plugged the power back in. A quick test proved it to be running smoothly and correctly.

Job Done.

CLICK HERE for ESPARES - The on-line parts store.

links to their European sites are in the footer of their page.

The stacking kit we use to put our dryer on top of the washing machine.

It includes a pull out shelf and a strong retaining strap to keep everything in place.

Another list of things we purchased. This time DIY and loft related.